The quality control throughout the whole spinning process is of fundamental importance. Knowing the fiber variability, during every step of the manufacturing process, reduces greatly the end product variability, improves the product quality and reduces the production cost. Tomsic Engineers, therefore, continue to develop high-quality testing equipment to provide spinners the total quality control in the spinning process.

TOMSIC is now pleased to introduce the AutoCount, very useful equipment used to test the count of the yarn directly in the Tomsic Evenness tester easy.

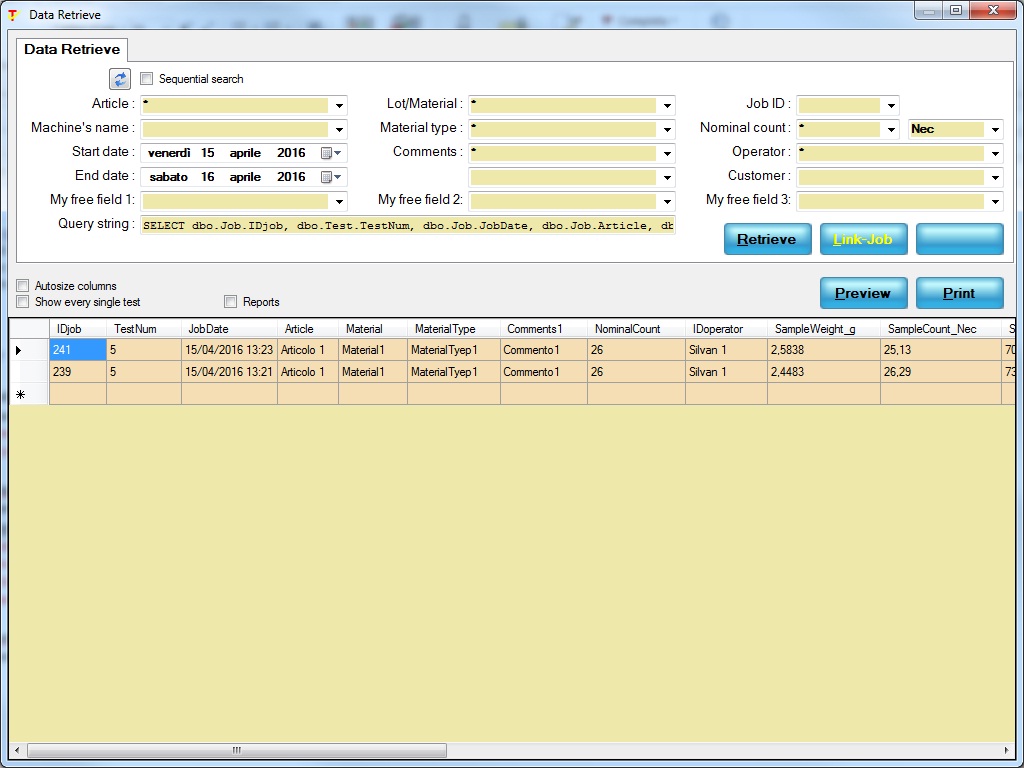

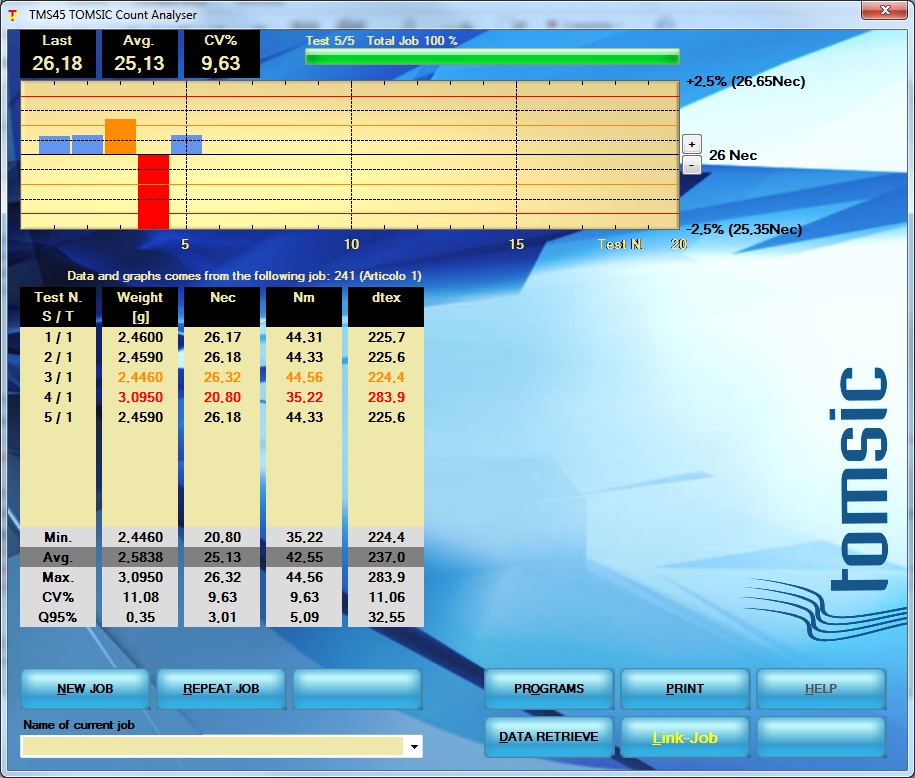

The AutoCount measures the weight of the tested yarn and provides the count variation (Average, CV%, Q95%, Min and Max values). All the AutoCount data are displayed in the same graphs of the evenness tester job. In practice, the AutoCount data complete the easy Evenness Tester reports with the weight and counts variation. The spinners have so the regularity data, the weight and count variation data of every test in only one report.

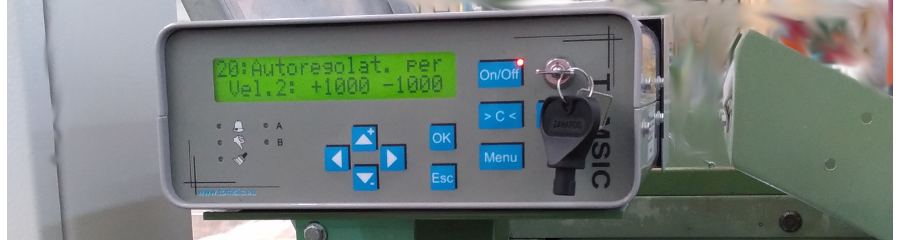

The Tomsic AutoCount module is directly connected with the easy Evenness tester software, the most operator-friendly software, installed on a normal PC with Windows 10 platform. Before running the test the operator can set the length of the tested yarn in the AutoCount. The evenness tester job begins with the test of the yarn regularity. During the evenness test, the same yarn is automatically pushed by the air pressure on the balance for the count test.

AutoCount provides an auto-cleaning process at the beginning and end of each test by air pressure.

Click here to view the evenness tester REPORT with AutoCount data

Tomsic

Tomsic