Product Description

Sugar Solution is a special solution for neutralize the glucose and oleic acid present in some types of cotton with various origin. It has a strong antistatic power too. Therefore it is ideal for the woolen and worsted spinning process of cotton and it is a must for the mixtures of cotton and synthetic fibers during the opening and carding process.

The sugar solution is composed by GLUCOSIL GSA 96 F.F., the combined composition of special compound antistatics mixed with phosphoric esters and hygroscopic conditioning components.

Advantages

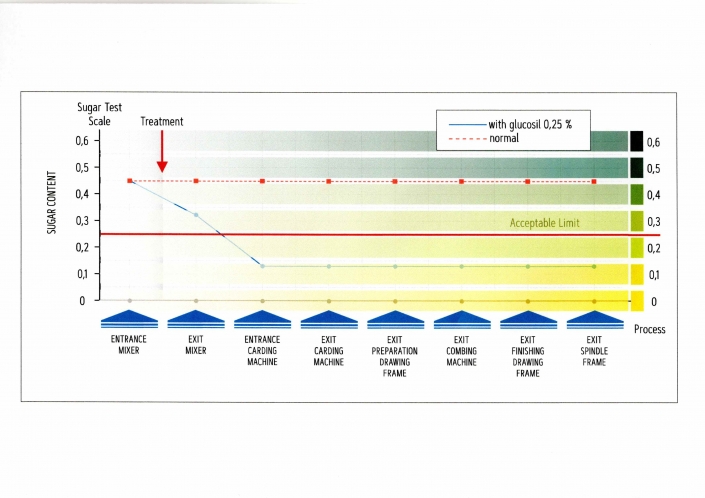

- Favors the woolen, worsted and open-end spinning process of cotton since it has property of neutralizing the glucose and oleic acid present in the raw cotton

- Avoids the formation of rolling up on the cylinders of the spinning frames, because reduces the sugar content in cotton

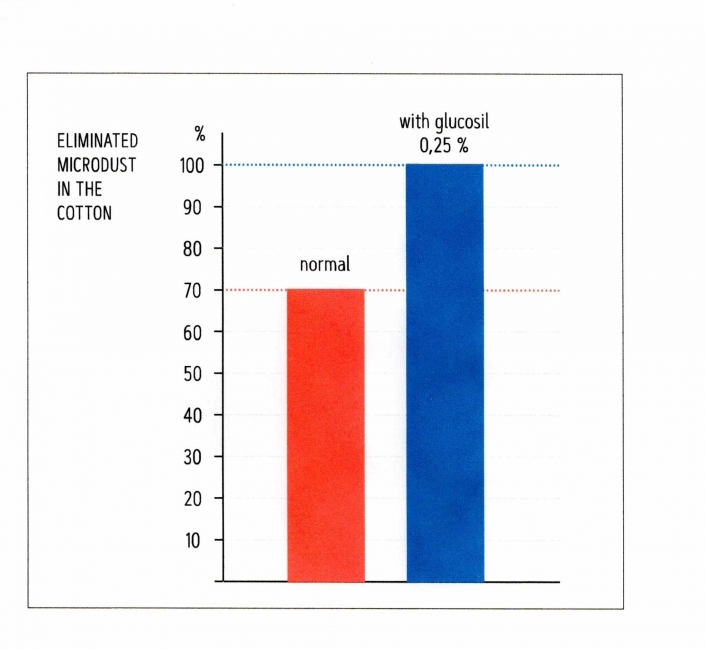

- The yarn treated with GLUCOSIL GSA 96 F.F. looks cleaner and less dusty during the opening and carding process. It thus improves the regularity, strength and quality of the yarn.

- Eliminates the static electrification. It is ideal for the mixtures of cotton and synthetic fibers processing

- Increases the relative humidity in the spinning room with consequent considerable reduction in the consumption of power

Properties and application range of Glucosil GSA96 F.F.:

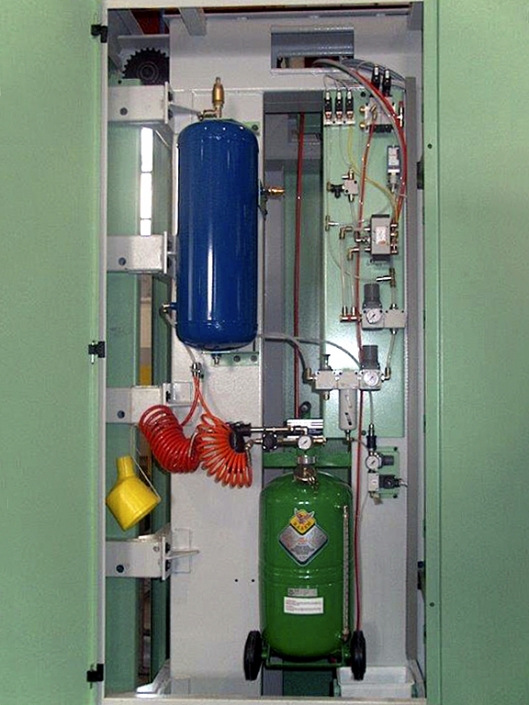

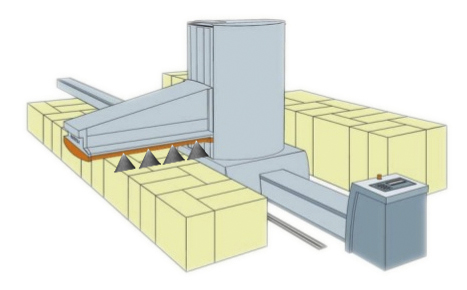

- Blender: The Glucosil GSA 96 F.F. is nebulized by the nebulizers installed on the blender or is sprayed directly on the mixture.

- Open bale: The Glucosil GSA 96 F.F. neutralizes the glucose and oleic acid present in the raw cotton. Due to the antistatic effect, the crystals and microdusts are sucked by the pneumatic transport system

- Carding machine: The removal of the crystals and the dust from the cotton fibers are intensified.

- Drawing frame: Better alignment, parallelization and uniformity of the sliver and less wrappings in the drafting cylinders.

- Comber: Thanks to the antistatic effect the GLUCOSIL reduces the formation of wrappings and improves the quality of the cotton web

- Roving frame: Better machine performance and less dust on the material

- Ring spinning: better yarn resistance and regularity, lower breakages per 1000 / f/h with the possibility of decreasing the yarn twisting

- Open end: less dust and more resistance of the yarn, more cleanliness of the rotors and opening roller